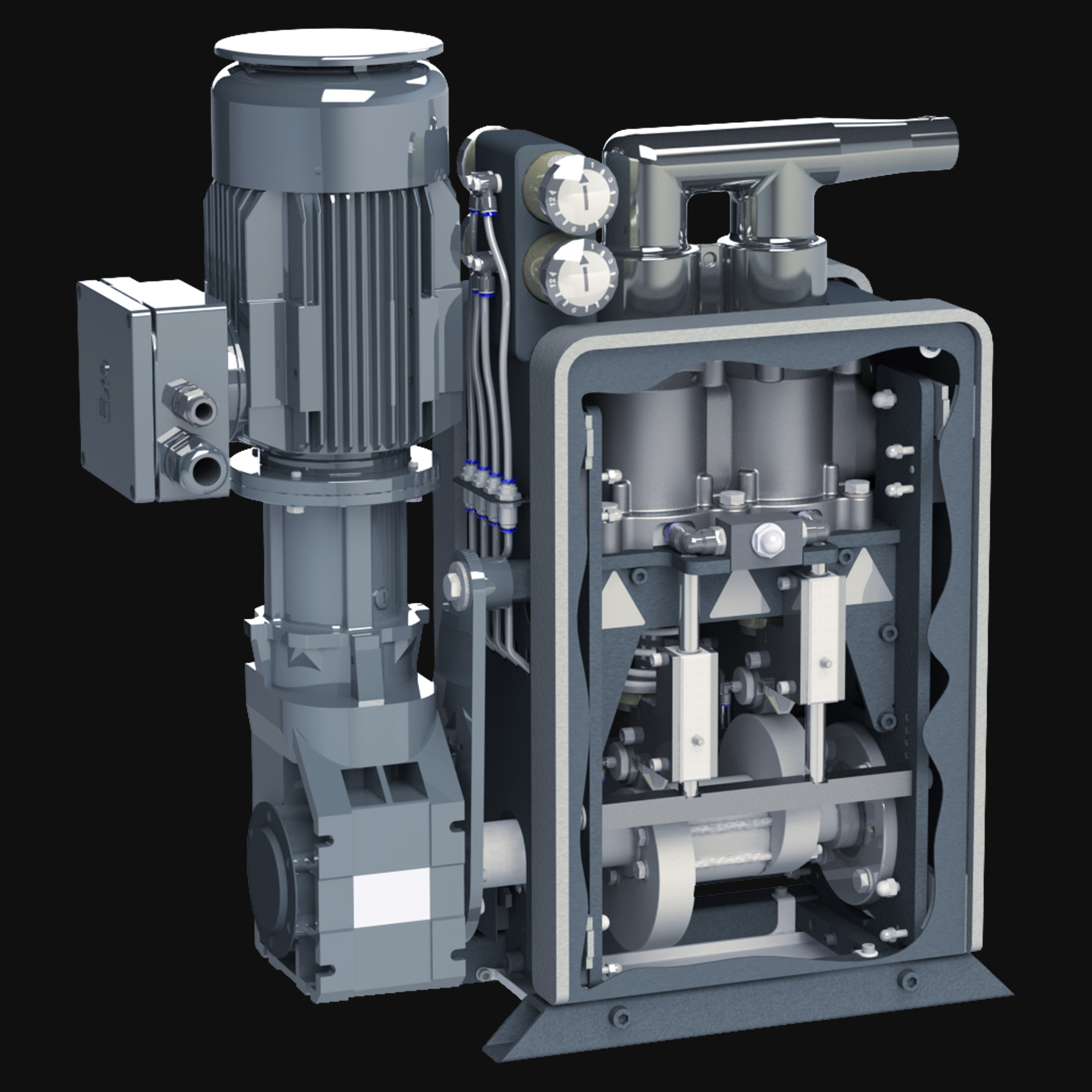

The electric piston pumps of the timECO series have been especially developed for paint supply systems. The small, compact design allows the integration of the pump without signifi - cant effort. This offers advantages, especially in retrofit projects.The pumps of the KPE-series also provide many other benefits.

• Low-shearing medium flow that increases the usability of the medium.

• Continuous lubricators, which ensure constant lubrication of the bearings.

• Matched piston drive kinematics ensure a uniform media flow.

• Vertically arranged pistons, which ensure a uniform load on the piston seals and thus better service life.

• Short piping lengths resulting in lower paint filling volumes. Sensors can be attached directly to the pump to monitor the system with minimal effort.

These variants are delivered with an intelligent sensor, which allows real-time testing of the rotational speed via a customer PLC. With connection of our tim®LINK module we enable many useful new features that increase profitability, process reliability and facilitate preventive maintenance. Simply integrate our tim®LINK module in your system and benefit from these advantages.

Fast response time

Vertically arranged pistons enable fast reaction times to keep the closed circular pipeline pressure constant.

Minimal pulsation

The unique cam disk kinematics ensure absolutely low pulsation flow delivery.

Compact design

The arrangement of pump, gearbox and motor enables a very compact design. This enables new systems to be planned with significantly less installation space and existing systems can be retrofitted without any problems.

Process monitoring

The built-in intelligent stroke sensor offers a wide range of options for increasing process reliability. In addition to the precise determination of maintenance intervals, real-time data output allows conclusions to be drawn about the current status of the process.

Minimal operating & maintenance costs

The durable guides and the maintenance- friendly design of the pump guarantee extremely low service costs. In addition, the built-in permanent lubricators ensure a significantly longer service life of the components.

Simple sensor connection

The special pressure pipe design allows up to 4 additional sensors to be integrated easily and without further installation effort. This efficient solution saves time and costs during implementation.

Cost savings |

|

|---|---|

| No compressed air systems required | |

| Reduced operating costs due to low power consumption | |

| Longer service life due to less wear | |

| Complete control of pump capacity via customer-provided controller | |

| Medium-friendly conveying | |

| High process reliability | |

| Easy maintenance due to modular design |

10 l/min

Piston pump timECO (electric)

PTI-KPE2010

Ready for Future

This pump is equipped with an intelligent sensor as standard. This opens up many new possibilities for you with your PLC in terms of economy, digitization, statistics, preventive maintenance and process optimization.

20 l/min

Piston pump timECO (electric)

PTI-KPE2020

Ready for Future

This pump is equipped with an intelligent sensor as standard. This opens up many new possibilities for you with your PLC in terms of economy, digitization, statistics, preventive maintenance and process optimization.

30 l/min

Piston pump timECO (electric)

PTI-KPE2030

Ready for Future

This pump is equipped with an intelligent sensor as standard. This opens up many new possibilities for you with your PLC in terms of economy, digitization, statistics, preventive maintenance and process optimization.

40 l/min

Piston pump timECO (electric)

PTI-KPE2040

Ready for Future

This pump is equipped with an intelligent sensor as standard. This opens up many new possibilities for you with your PLC in terms of economy, digitization, statistics, preventive maintenance and process optimization.

60 l/min

Piston pump timECO (electric)

PTI-KPE2060

Ready for Future

This pump is equipped with an intelligent sensor as standard. This opens up many new possibilities for you with your PLC in terms of economy, digitization, statistics, preventive maintenance and process optimization.